Whitepapers

Welding Inspection

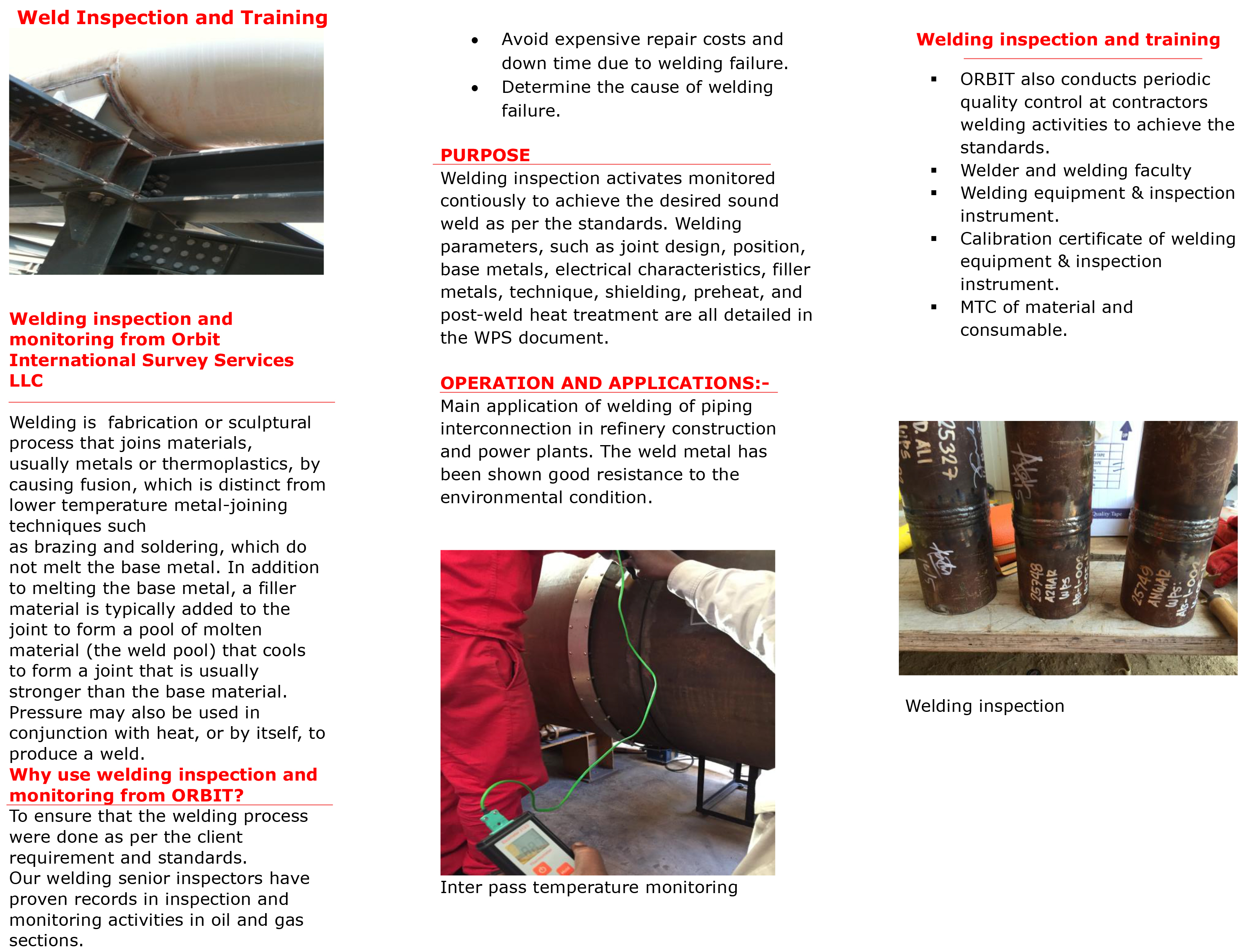

Welding is fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing fusion, which is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal. In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that is usually stronger than the base material. Pressure may also be used in conjunction with heat, or by itself, to produce a weld.

3LPP Coating

Ensure your coating work is protecting your assets and prevent future coating failures. Whether your assets include the management of construction sites, factories, laboratories, shipyards or power plants, you need to be certain that your coating work is protecting your facility. Coating failures mean expensive repair costs and lengthy downtime. Our coating inspection and failure analysis helps ensure the continued protection of your facility.

GRE Inspection

Welcome to Orbit International Survey Services LLC in the Middle east and Asia's leader in Quality Assurance to a manufacturing of composite large diameter fiberglass pipe system. Orbit offers bespoke Glass Fiber Reinforced Epoxy (GRE) pipe system verification solutions for the water, Oil & Gas and industrial sectors. Through its pioneering use of fiberglass inspection technique, service excellence and product technologies, ORBIT is an Inspection pioneer in the conversion of steel pipe into fiberglass.

Neoprene coating

Ensure your coating work is protecting your assets and prevent future coating failures. Whether your assets include the management of construction sites, factories, laboratories, shipyards or power plants, you need to be certain that your coating work is protecting your facility. Coating failures mean expensive repair costs and lengthy downtime. Our coating inspection and failure analysis helps ensure the continued protection of your facility.

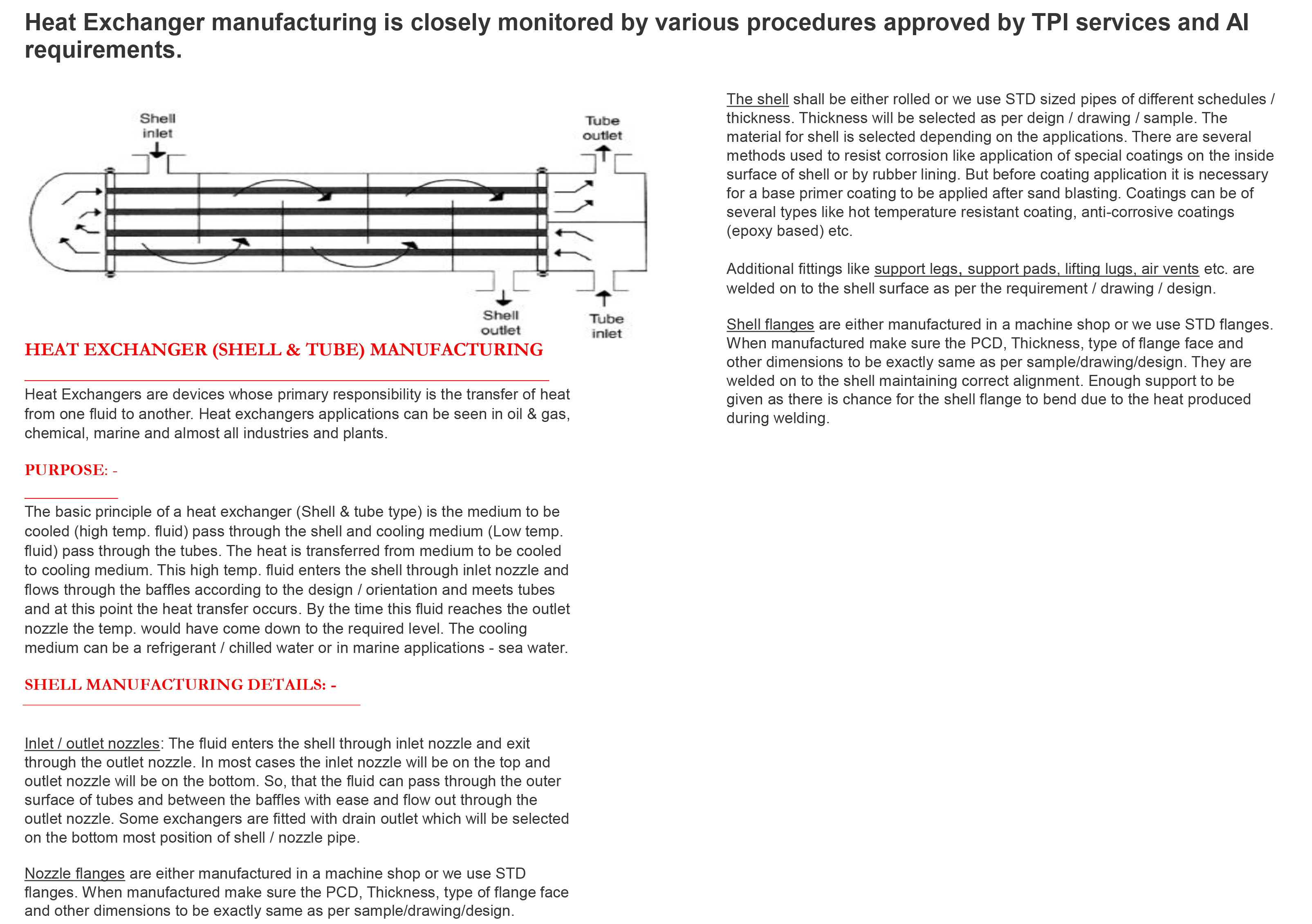

Heat Exchangers

The basic principle of a heat exchanger (Shell & tube type) is the medium to be cooled (high temp. fluid) pass through the shell and cooling medium (Low temp. fluid) pass through the tubes. The heat is transferred from medium to be cooled to cooling medium. This high temp. fluid enters the shell through inlet nozzle and flows through the baffles according to the design / orientation and meets tubes and at this point the heat transfer occurs. By the time this fluid reaches the outlet nozzle the temp. would have come down to the required level. The cooling medium can be a refrigerant / chilled water or in marine applications - sea water.